GUWAHATI: Researchers at the Indian Institute of Technology Guwahati (IIT-G) have developed technology to convert tea waste generated by the tea industry into a spectrum of innovative, eco-friendly products.

Aligning with the Waste to Wealth (W2W) mission of the Centre, the array of value-added products developed in their laboratory include low-cost antioxidant-rich supplements, organic preservatives, pharmaceutical super-grade activated carbon, biochar, liquefiable carbon source, micro and nano-crystalline cellulose, and carbon quantum dots.

As tea consumption worldwide continues to surge, with projections reaching 7.4 million tonnes by 2025, it is accompanied by a surge in industrial tea waste generation. The disposal of this waste poses a challenge, given its high lignin content and low inorganic components. IIT Guwahati’s research addresses these issues, promoting sustainable practices and innovative solutions to ensure both industrial growth and environmental preservation.

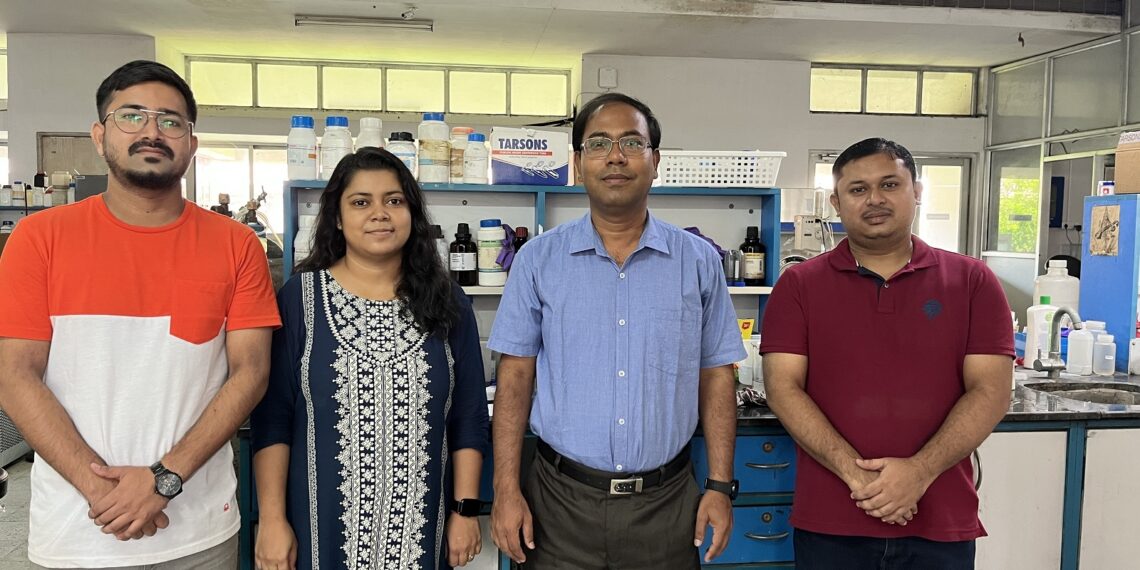

Led by Prof. Mihir Kumar Purkait of the Department of Chemical Engineering, the research team has undertaken pioneering research on the versatile applications of tea factory waste. This project has emerged as a result of the Abdul Kalam Technology Innovation National Fellowships by the Indian National Academy of Engineering (INAE).

The research team has filed multiple patents based on these developments, including technologies related to catechin-based organic preservatives for fruit juices and pharmaceutical-grade super-activated carbon. These findings have been published in various international journals, underscoring their significance.

Prof. Purkait highlighted the potential of catechin-based capsules, stating, “These capsules offer users the benefits of catechins without the need for multiple cups of green tea, catering to the increasing demand for antioxidant-rich supplements.”

Discussing the transformation of spent tea leaves into activated carbon, Prof. Purkait added, “This involves a dual-step procedure, first carbonization, followed by activation, creating a porous structure for a wide range of applications, including food grade activated carbon, natural-based abrasives, pharmaceutical ingredients, anti-pollution masks, and packaging materials.”

The commercial use of these products is substantial, with increasing demand from health-conscious consumers and food processing companies. The project’s immediate future plans involve advancing to the advanced pilot stage (TRL-7), leading to the transfer of technology (ToT) to potential industry partners. These value-added products not only enhance the economic viability of tea cultivation but also promote sustainable practices by reducing waste and enhancing resource efficiency.