Kokrajhar (Assam): In less than a decade, silk has gone from a household craft to a cornerstone of rural income across the Bodoland Territorial Region (BTR).

What once served as a cultural practice of the Bodo and other tribal communities — mainly the rearing of eri silkworms by women for family use — is now driving jobs, exports, and recognition on the global stage.

The turning point came in 2024, when Bodo Eri Silk secured the coveted Geographical Indication (GI) tag, giving the fabric a distinct identity in textile markets.

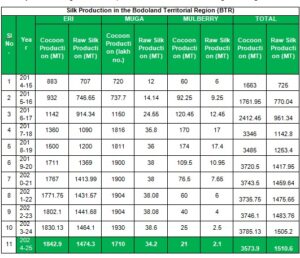

This formal recognition coincided with a sharp rise in raw silk output, which doubled in ten years to touch 1,510 metric tons in 2024–25.

Officials say nearly half of the villages in the BTR are engaged in sericulture today, with over 41,000 acres of land under silkworm food crops and 44,000 households reaping the benefits.

The Bodoland Sericulture Mission has been central to this transformation. Rolled out by the Bodoland Territorial Council in partnership with the Central Silk Board, Ministry of Textiles, NEHHDC, APART, and NTPC-Bongaigaon, the programme covers the entire value chain — from seed supply and plantation to spinning and weaving.

Since its launch, more than 6,000 families have received training, infrastructure, and technology support worth about Rs. 50,000 per household.

Infrastructure investments have accelerated the momentum. In January 2025, a spun silk mill began operating in Barama, Baksa district, with funding of Rs. 14.92 crore from the North Eastern Council.

Capable of producing 461 kilograms of yarn a day, it employs 375 workers and assures cocoon procurement for nearly 50,000 households.

Later in August, another unit was inaugurated at Kokrajhar’s Bodoland Silk Park with Rs. 13.39 crore from the Central Silk Board.

It is projected to generate 37 metric tons of yarn annually, create 90 jobs, and sustain over 15,000 families.

Beyond production, the mills have offered something equally valuable: price stability and direct market access.

For the first time, weavers and rearers are seeing steady offtake of cocoons, cutting out middlemen and reducing risks.

The NEHHDC has already started marketing certified yarn from Baksa, targeting fashion industries that value ethical, sustainable textiles.

With Assam already leading India’s eri and muga silk production, Bodoland’s expansion strengthens the state’s reputation as the country’s sericulture hub.

ALSO READ: Alcaraz defeats Sinner to clinch sixth Grand Slam and reclaim World No. 1

Challenges, however, remain. Experts point to the need for timely working capital, reliable cocoon procurement at fair prices, and stronger linkages between women’s groups, mills, and premium textile buyers.

Still, the difference on the ground is undeniable.

From Kokrajhar and Chirang to Baksa, Udalguri, and Tamulpur, women-led producer groups are reporting higher earnings, quicker sales, and more confidence in treating sericulture as a stable second income.

As production capacities grow and new partnerships develop, Bodoland’s “peace silk” is emerging not just as a traditional fabric but as a symbol of empowerment, sustainability, and regional pride — weaving together the future of thousands of families with threads of opportunity.